I thought I spoke English until a bus driver in Cork threw me...

The Power of small Micro-Electronics Projects

A Blog Post

This anecdote demonstrates the power of small micro-electronics projects. With a small investment in time and money, I was able to solve a problem that was time-consuming and anoying.

The other day, I encountered a simple yet crucial problem during my master’s thesis field trial: How to precisely measure the amount of water we were irrigating.

Problem Description

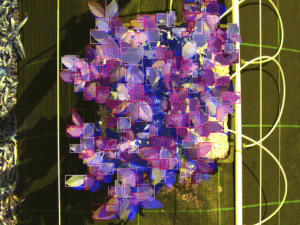

The experimantal field of my master’s thesis field is irrigated to prevent potatoes from experiencing water stress. The required amount of water is calculated based on the evapotranspiration of the plants and the soil moisture content, which is measured by sensors. The irrigation system is a drip irrigation system controlled by a manual cut-off valve. The water amount is measured by a water meter that short-circuits two wires for every liter flowing through the pipe. The entire system is composed of three independent irrigation zones, each with its own water meter and cut-off valve.

The challenge was that before and after each irrigation event, I had to manually read the water meter and record the values. This process was not only time-consuming but also prone to errors. Sometimes, irrigation tubes would rupture, causing water to spill in large amounts over small parts of the field. These events could go undetected for up to an hour, leading to significantly inflated water meter readings, due to drasticly increased flow rates.

The Solution

I decided to dedicate one day to finding a solution to this problem. The idea was to use a small microcontroller to read the water meter by measuring the resistance between the two wires from the water meter. The microcontroller would then save the data to an SD card, which could later be read on a computer. This setup would allow to calculate the amount of water flowing through the pipe and detect leaks due to higher-than-expected water flow rates. The excess water from leaks could then be subtracted from the total amount of water recorded. The logger would also need to be solar-powered, with a battery backup due to a lack of power outlets in the field. Furthermore, it would need to be waterproof and withstand outdoor conditions.

The Implementation

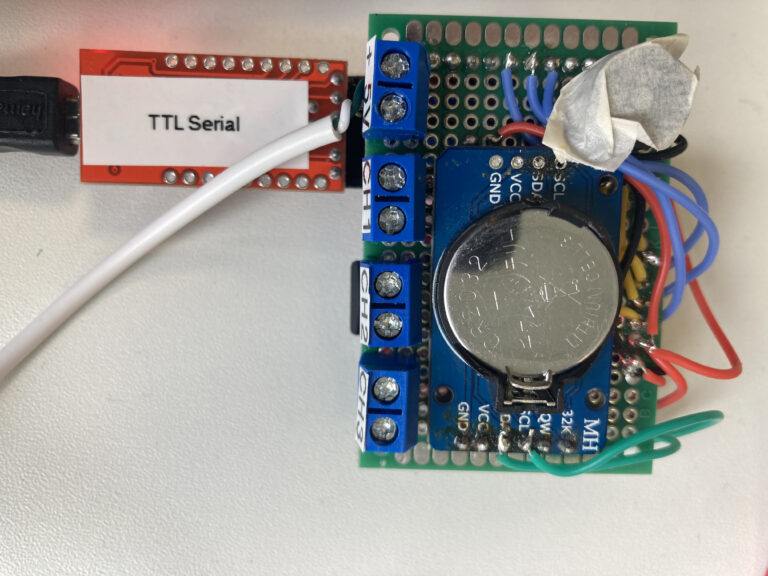

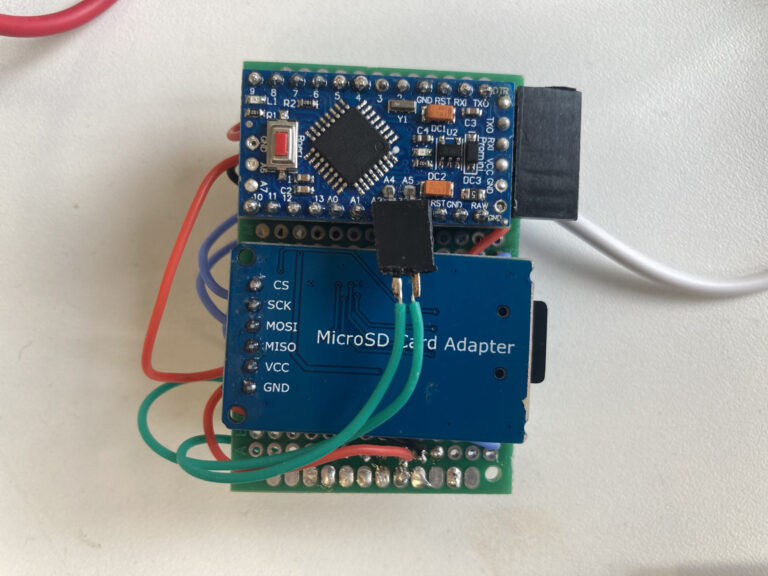

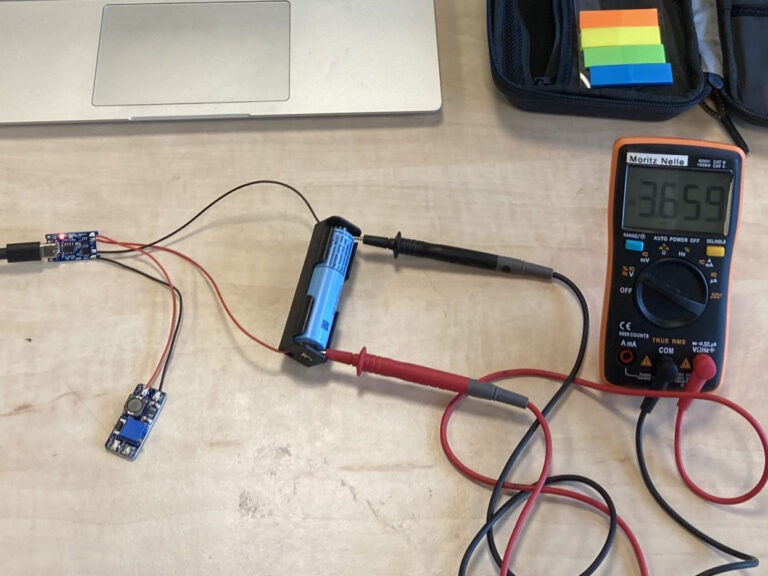

An Arduino Pro Mini, a small and easy-to-program microcontroller board was used as the brain of the logger. Each wire pair, comming from the water meter was connected, one to the 5V terminal of the Arduino and the other to a digital input pin. I used a 1kΩ resistor to pull the input pin to ground when the water meter was not short-circuited. The data was saved in a CSV file on an SD card with a timestamp (obtained from a real-time clock) and the ID number of the irrigation system (1, 2, and 3). The Arduino was powered by a 3.7V 18650 LiPo battery charged by a small solar panel. The entire setup was enclosed in a 3D printed enclosure.

The Power of Small Micro-Electronics Projects

This anecdote demonstrates the power of small micro-electronics projects. With a small investment in time and money, I was able to solve a problem that was not only time-consuming but also error-prone. The solution was simple yet effective, allowing me to focus on other aspects of my research. Rapid prototyping can be highly beneficial. By quickly building a working model, you can test your ideas in real-world conditions and make necessary adjustments. This approach saves time and resources compared to spending months planning and designing a perfect solution that might not be needed.

Industrial solutions are often much more expensive, especially if you need only simple solutions. In my case, a commercial irrigation monitoring system would have cost hundreds if not thousands of euros, which was not feasible for my research budget. By creating a custom solution using readily available components, I achieved the same functionality (for my application) at a fraction of the cost (around 15 euros). Building your own solution allows for greater flexibility and customization. You can tailor the system to meet your specific needs and easily make modifications as requirements change.

Small micro-electronics projects empower individuals, researchers, and businesses to solve specific problems quickly and cost-effectively. Rapid prototyping and custom solutions can provide significant advantages over expensive industrial alternatives, especially for simple but unique requirements. This approach not only saves time and money but also fosters innovation and creativity. So, next time you face a problem, consider building a small micro-electronics project to solve it. You might be surprised by how much you can achieve with a little bit of electronics knowledge and creativity.

Please find the Arduino Code and platformIO settings in the correspoding GitHub repo: GitHub Repo: Irrigation_Logger

Other Posts from all Categories

PhenoSelect: Training a Neural Network Because I Refuse to Click on 100,000 Leaves

An introduction to PhenoSelect, an open-source deep learning pipeline designed to automate leaf...

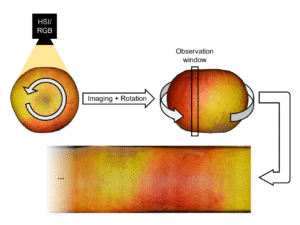

How to Image a Whole Apple

A deep dive into the process of building a custom hardware and software...

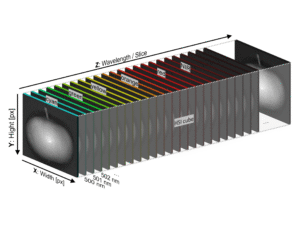

Beyond the Naked Eye OR Why More Data Isn’t Always Better

An exploration into how hyperspectral imaging and machine learning can be used to...